Anti-static packaging finds its primary application in electronic manufacturing companies, electronic components, children's toys, flammable and explosive materials, as well as clothing packaging, storage, and transportation. These diverse use cases necessitate different specifications for anti-static treatment, especially in situations where safety and product preservation are at stake.

In order to mitigate risks in critical scenarios and adhere to safety standards, strict compliance with ESD S1 specifications for anti-static packaging bags or films is imperative. However, not all situations require the same level of anti-static protection, and ESD S3 specification anti-static packaging bags/films may suffice. This underscores the importance of manufacturers of anti-static packaging materials having the capability to produce a wide range of anti-static levels and specifications, including size, material type, thickness, and shape. The high procurement volume of these packaging materials also places significant demands on production capacity and efficiency.

Drawing from over a decade of experience as a manufacturer of solventless laminating equipment, we possess a deep understanding of the anti-static requirements within the flexible packaging industry. Our solventless machines seamlessly integrate with printing equipment, bag-making equipment, and cutting equipment, creating comprehensive flexible packaging production lines. These production lines enable efficient batch production of anti-static packaging bags and films with various anti-static levels and specifications.

To further streamline the operations of flexible packaging companies, we have simplified the user interface and incorporated customizable language packages. This simplification enhances the convenience of operating our solventless lamination equipment. Additionally, we have harnessed advanced remote IoT technology to minimize downtime during production. With proper authorization, we can provide remote assistance for the maintenance of the solventless lamination equipment, ensuring uninterrupted operations.

After more than a decade of dedicated development, our solventless lamination equipment has garnered trust and recognition from flexible packaging companies worldwide. It is the preferred choice of flexible packaging companies in over thirty countries and regions, with more than 2500 companies benefitting from its capabilities, earning their trust and mutual support.

In the anti-static packaging industry, if you have a need for solventless laminating machines, we recommend ours.

-

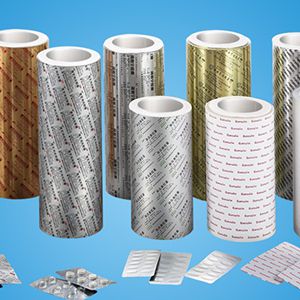

- WRJ i9-1300A (2-layer Lamination) Simple operation is the ultimate principle The solventless lamination machine is primarily designed for the production of flexible packaging by bonding two layers of flexible films with solventless adhesive. It joins together different flexible packaging webs to create a two-layer structure as the packaging laminate for various industries such as food, pharmaceutical, personal care & cosmetic, anti-static packaging, EMI shielding, construction, decoration & renovation, and more. More Info

-

- WRJ Fi9-1300A (2-layer Lamination) Consuming less power, lower operation costs The solventless laminator provides the eco-friendly solution of solvent-free adhesive coating while ensuring precise coating weight consistency, thus serving as a popular choice for the manufacturers of flexible laminates that are suitable for product packaging. The lamination machine is commonly used to produce flexible packaging that consists of two substrates (generally 7µm -120µm in thickness) made of BOPP, PET, Nylon, CPP, PE, VMPET, VMCPP, PVC, etc. More Info

-

- TRI-1300A (3-layer Lamination) Aluminum foil, low loading, short path, no adhesive penetration Our SINSTAR three-layer solventless lamination machine is mainly applied to produce flexible packaging laminates for the a multitude of market sectors including food, pharmaceuticals, personal care items, anti-static materials, insulation materials, building materials and decoration. More Info

If you have specific requirements on these three solventless lamination machines, please contact us immediately, we also offer customization services.