In the construction industry, where the demand for high-performance aluminum foil laminated materials is substantial, our company steps in as a reliable partner. Our solventless lamination equipment offers the necessary strength and technical support to building materials manufacturers. Versatile in its capabilities, our lamination equipment can handle various material combinations, including aluminum/plastic, plastic/plastic, plastic/paper, silver/paper, non-woven/plastic, and more. This versatility caters to the insulation and thermal insulation requirements of ductwork system in construction.

We have fine-tuned our processes to enable large-scale and rapid material processing. Our equipment is designed for user-friendliness, making it easy to operate. Moreover, we have implemented remote fault resolution technology, empowering building materials manufacturers to concentrate on producing laminating tape products. This approach not only reduces the costs associated with training new equipment operators and maintenance personnel but also minimizes losses stemming from equipment failures.

In a world increasingly focused on environmental protection, industries are actively seeking ways to reduce environmental pollution caused by manufacturing processes. Our solventless lamination solution aligns seamlessly with this global imperative. Furthermore, by utilizing solventless lamination technology, our equipment prioritizes the well-being of production personnel during operations. This holistic approach ensures that our solventless lamination equipment receives a warm welcome from building materials manufacturers, who appreciate its eco-friendliness and commitment to worker health.

In the anti-static packaging industry, if you have a need for solventless laminating machines, we recommend ours.

-

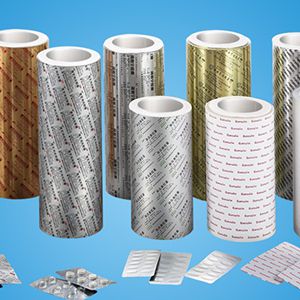

- WRJ i9-1300A (2-layer Lamination) Simple operation is the ultimate principle The solventless lamination machine is primarily designed for the production of flexible packaging by bonding two layers of flexible films with solventless adhesive. It joins together different flexible packaging webs to create a two-layer structure as the packaging laminate for various industries such as food, pharmaceutical, personal care & cosmetic, anti-static packaging, EMI shielding, construction, decoration & renovation, and more. More Info

-

- WRJ Fi9-1300A (2-layer Lamination) Consuming less power, lower operation costs The solventless laminator provides the eco-friendly solution of solvent-free adhesive coating while ensuring precise coating weight consistency, thus serving as a popular choice for the manufacturers of flexible laminates that are suitable for product packaging. The lamination machine is commonly used to produce flexible packaging that consists of two substrates (generally 7µm -120µm in thickness) made of BOPP, PET, Nylon, CPP, PE, VMPET, VMCPP, PVC, etc. More Info

-

- TRI-1300A (3-layer Lamination) Aluminum foil, low loading, short path, no adhesive penetration Our SINSTAR three-layer solventless lamination machine is mainly applied to produce flexible packaging laminates for the a multitude of market sectors including food, pharmaceuticals, personal care items, anti-static materials, insulation materials, building materials and decoration. More Info

If you have specific requirements on these three solventless lamination machines, please contact us immediately, we also offer customization services.