In both office and residential interior decoration, the use of decorative materials like aluminum foil and wallpaper is a common practice. The architectural decorative materials market is characterized by substantial demand, and there's a growing trend towards personalization. Consequently, decorative material manufacturers are faced with increasingly stringent requirements for lamination technology.

As a trusted partner to building material manufacturers, we offer all-encompassing solutions for the processing of decorative materials. Our goal is to assist manufacturing companies in boosting production capabilities and facilitating personalized production to meet the evolving market demands.

We employ solventless lamination technology, a key factor contributing to the popularity of products manufactured using our lamination technology among decorative material manufacturers. Solventless lamination significantly reduces environmental pollution throughout the production process, prioritizing the well-being of personnel involved. The final products exhibit minimal secondary pollution, thereby having a minimal impact on the environment.

Moreover, when these products are used, such as decorative film in offices or wallpaper in homes, they emit minimal harmful gases due to temperature increases. This emphasizes the well-being and safety of end-users. The eco-conscious approach of our solventless lamination equipment has made it a highly sought-after choice among decorative material manufacturers.

In the EMI shielding & insulation materials industry, if you have a need for solventless laminating machines, we recommend ours.

-

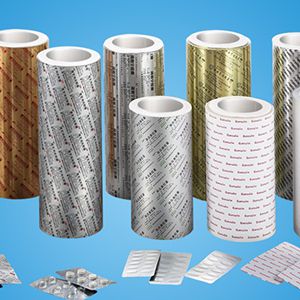

- WRJ i9-1300A (2-layer Lamination) Simple operation is the ultimate principle The solventless lamination machine is primarily designed for the production of flexible packaging by bonding two layers of flexible films with solventless adhesive. It joins together different flexible packaging webs to create a two-layer structure as the packaging laminate for various industries such as food, pharmaceutical, personal care & cosmetic, anti-static packaging, EMI shielding, construction, decoration & renovation, and more. More Info

-

- WRJ Fi9-1300A (2-layer Lamination) Consuming less power, lower operation costs The solventless laminator provides the eco-friendly solution of solvent-free adhesive coating while ensuring precise coating weight consistency, thus serving as a popular choice for the manufacturers of flexible laminates that are suitable for product packaging. The lamination machine is commonly used to produce flexible packaging that consists of two substrates (generally 7µm -120µm in thickness) made of BOPP, PET, Nylon, CPP, PE, VMPET, VMCPP, PVC, etc. More Info

-

- TRI-1300A (3-layer Lamination) Aluminum foil, low loading, short path, no adhesive penetration Our SINSTAR three-layer solventless lamination machine is mainly applied to produce flexible packaging laminates for the a multitude of market sectors including food, pharmaceuticals, personal care items, anti-static materials, insulation materials, building materials and decoration. More Info

If you have specific requirements on these three solventless lamination machines, please contact us immediately, we also offer customization services.